Pressure Seal Lift Check Valve for Power Station

H61Y-200 H61Y-250 H61Y-320 high voltage valve pipe ends welded structure, welding groove can be made according to the standard or user requirements, is suitable for the thermal power plant, petrochemical, metallurgical and other high temperature and high pressure steam, water, oil, steam pipe for preventing device of medium flow. One is the introduction of ANSI B16.34 and JIS type according to E101 standard;

Structure Characteristics

1. The valve flap quenching, and can move on the body, medium back, by the medium pressure and the automatic valve valve spring.

2. Valve body, valve cover for die forgings.

3. The valve seat sealing surface using cobalt based alloy plasma spray surface. Wear resistance and good anti abrasion performance.

4. Check valve should be installed in horizontal pipelines medium flows from

down to up.

Materials

| Model | Part Name | |||||||

| Body | Disc | Spring | Stem | Gasket | Plate | Bonnet | Lock Nut | |

| H61Y-250 H61Y-320 |

Carbon Steel | Carbon Steel | Spring Steel | Stainless Steel | Flexible Graphite | Carbon Steel | Carbon Steel | High Quality Carbon Steel |

| H61Y-P54100V H61Y-P57170V |

Chrome Vanadium Steel | Chrome Vanadium Steel | Spring Steel | Chrome Vanadium Steel | Flexible Graphite | Chrome Vanadium Steel | chrome Vanadium Steel | Chromium Steel |

Specification

| Nominal Pressure (MPa) |

Test Pressure (MPa) |

Working Pressure | Working Temperature (°C) | Applicable Fluid | |||

| Strength | Seal (Liquid) | P54 | P55 | P57 | |||

| 10.0 | 15.0 | 11.0 | ≤ 425 | Water, Steam, Oil | |||

| 16.0 | 24.0 | 17.6 | |||||

| 20.0 | 30.0 | 22.0 | |||||

| 25.0 | 37.5 | 27.5 | |||||

| 32.0 | 48.0 | 36.0 | |||||

| P5410 | 30.0 | 22.0 | 10 | ≤ 540 | Steam | ||

| P5414 | 37.5 | 27.5 | 14 | ||||

| P5417 | 48.0 | 36.0 | 17 | ||||

| P5510 | 37.5 | 27.5 | 10 | ≤ 550 | |||

| P5514 | 48.0 | 36.0 | 14 | ||||

| P5517 | 53.0 | 39.0 | 17 | ||||

| P5710 | 48.0 | 36.0 | 10 | ≤ 570 | |||

| P5714 | 55.0 | 40.0 | 14 | ||||

| P5717 | 60.0 | 44.0 | 17 | ||||

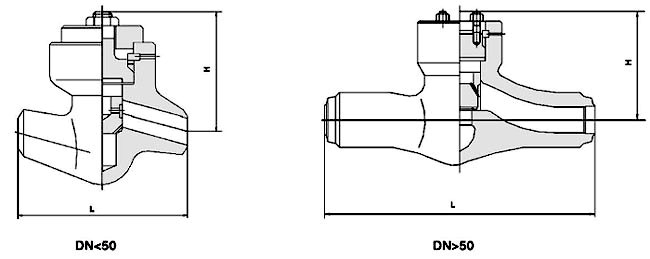

Dimensions & Weights

| GB 25.0MPa | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| GB 32.0MPa | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P54140V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P54170V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P57170V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

All Categories

- Ball Valves

- Control Valves

- Check Valves

- Globe Valves

- Butterfly Valves

- Bellows Sealed Valves

- Pressure Reducing Valves

- Plug Valves

- Safety Valves

- Safety Relief Valves

- Resilient Seated Gate Valves

- Cast Steel Valves

- Forged Steel Valves

- Instrumentation Ball Valves

- Instrument Manifolds

- Needle & Gauge Valves

- Balance Valves