API 602 Forged Swing / Piston Check Valve

Applicable Standards

• STEEL CHECK VALVES, API 602

• STEEL VALVES, ASME B16.34

• FACE TO FACE, MANUFACTURER STANDARD

• FACE TO FACE, FLANGED, ASME B16.10

• END FLANGES, ASME B16.5

• BUTT WELDING ENDS, ASME B16.25

• SOCKET-WELDING ENDS, ASME B16.11

• SCREWED ENDS, ASME B1.20.1

• INSPECTION AND TEST, API 598

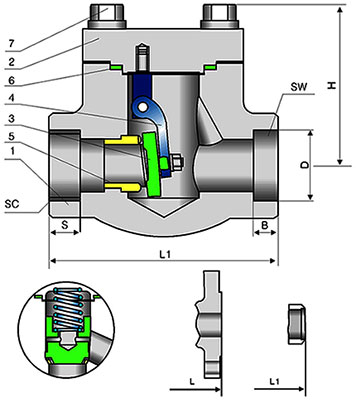

Design Descriptions

• BOLTED COVER

• SEAT RINGS INTEGRAL WITH BODY OF LIFT

• HORIZONTAL OR VERTICAL SERVICE

• SOCKET-WELDING ENDS (SW), THREADED ENDS

• BUTTWELDING ENDS (BW), FLANGED ENDS

• CL 800 - 1500 Lb

Materials

| No | Part Name | ASTM Materials C-Si 16Cr-12Ni-2Mo 11/4Cr-1/2Mo-Si |

||

| 1 | Body | A105 | A182-F316 | A182-F11 |

| 2 | Cover | A105 | A182-F316 | A182-F11 |

| 3 | Disc | A182-F6a | A182-F316 | A182-F6A+HF |

| 4 | Hinge | A276-410 | A276-316 | A276-410 |

| 5 | Seat | A276-410 | A182-F316 | A276-410+HF |

| 6 | Gasket2) | Graphite+304 | Graphite+316 | Graphite+304 |

| 7 | Stud | A193-B7 | A193-B8M | A193-B16 |

Note:

1) Lift type check valve seat ring integral with body.

2) Spiral wound construction.

Dimensions & Weights

| NPS DN |

Unit | L11) | L (Flanged Ends) | d | SW | SC | H | WT2)(kg) | ||||

| 150 Lb 300 Lb 600 Lb | D | B | NPT | S | ||||||||

| 3/8 | in | 3.12 | 4.00 | 6.00 | 6.50 | 0.354 | 0.693 | 0.378 | 3/8 | 0.540 | 2.40 | 3.8 / 2.8 |

| 10 | mm | 79 | 102 | 152 | 165 | 9 | 17.6 | 9.6 | 13.6 | 61 | ||

| 1/2 | in | 3.12 | 4.25 | 6.00 | 6.50 | 0.354 | 0.858 | 0.378 | 1/2 | 0.535 | 2.40 | 5.6 / 3.4 |

| 15 | mm | 79 | 108 | 152 | 165 | 10 | 21.8 | 9.6 | 13.6 | 61 | ||

| 3/4 | in | 3.62 | 4.62 | 7.00 | 7.50 | 0.512 | 1.067 | 0.500 | 3/4 | 0.547 | 2.40 | 7.8 / 4.7 |

| 20 | mm | 92 | 117 | 178 | 190 | 13 | 27.1 | 12.7 | 13.9 | 61 | ||

| 1 | in | 4.38 | 5.00 | 8.00 | 8.50 | 0.689 | 1.331 | 0.500 | 1 | 0.681 | 3.07 | 12.5 / 9.2 |

| 25 | mm | 111 | 127 | 203 | 216 | 17.5 | 33.8 | 12.7 | 17.3 | 78 | ||

| 11/4 | in | 4.75 | 5.50 | 8.50 | 9.00 | 0.906 | 1.677 | 0.500 | 1-1/4 | 0.709 | 3.31 | 17 / 10.5 |

| 32 | mm | 120 | 140 | 216 | 229 | 23 | 42.6 | 12.7 | 18 | 84 | ||

| 1l/2 | in | 4.75 | 6.50 | 9.00 | 9.50 | 1.142 | 1.917 | 0.500 | 1-1/2 | 0.724 | 10.25 | 23.5 / 13.3 |

| 40 | mm | 120 | 165 | 229 | 241 | 30 | 48.7 | 12.7 | 18.4 | 3.98 | ||

| 2 | in | 5.50 | 8.00 | 10.50 | 11.50 | 1.378 | 2.406 | 0.626 | 2 | 0.756 | 4.72 | 38.8 / 18.9 |

| 50 | mm | 140 | 203 | 267 | 292 | 35 | 61.1 | 15.9 | 19.2 | 120 | ||

All Categories

- Ball Valves

- Control Valves

- Check Valves

- Globe Valves

- Butterfly Valves

- Bellows Sealed Valves

- Pressure Reducing Valves

- Plug Valves

- Safety Valves

- Safety Relief Valves

- Resilient Seated Gate Valves

- Cast Steel Valves

- Forged Steel Valves

- Instrumentation Ball Valves

- Instrument Manifolds

- Needle & Gauge Valves

- Balance Valves