Stainless Steel Safety Relief Valve, Closed

Technical Data

Stainless Steel Safety Relief Valves, Closed

| Normal Pressure | Class | 150 | 300 | 600 | 900 | 1500 |

| Body strength | Ps (MPa) | 3.0 | 7.5 | 15 | 22.5 | 38 |

| Set pressure | Pk (MPa) | 0.1~2 | 1.6~5 | 3.2~10 | 8~15 | 10~25 |

| Seal pressure | Pm | 90Pk | ||||

| Reseating pressure | Ph | =90Pk | ||||

| Relieving pressure | Pp | =1.1Pk | ||||

| Lift | H (mm) | =1/20 do | ||||

| Appropriate temperature | C | =300°C | ||||

| P,R | =200°C | |||||

| Appropriate medium | Air, Oil, Steam, Water, Corrosive medium | |||||

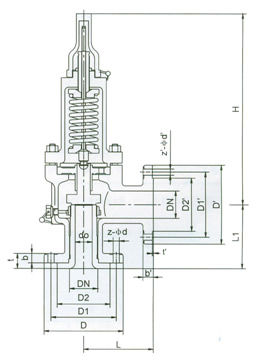

Dimensions (mm)

| Type | DN | do | d | M | D | K | Z-∮d | b | d1 | M1 | D1 | K1 | Z1-∮d1 | b1 | L | L1 | ~H |

| A41Y-160 | 15 | 8 | 20 | M24×2 | 95 | 60 | 3-18 | 20 | / | M33×2 | 36 | / | / | / | 50 | 80 | 85 |

| 20 | 10 | 25 | M27×2 | 95 | 60 | 3-18 | 20 | / | M33×2 | 48 | / | / | / | 50 | 80 | 85 | |

| 25 | 12 | 28 | M33×2 | 105 | 68 | 3-18 | 20 | / | M33×2 | 48 | / | / | / | 50 | 80 | 85 | |

| A41Y-160 | 10 | 8 | 18 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 |

| 15 | 8 | 20 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 20 | 10 | 27 | M33×2 | 105 | 68 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 25 | 12 | 28 | M42×2 | 105 | 68 | 3-18 | 20 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 32 | 12.14.16 | 37 | M52×2 | 115 | 80 | 4-18 | 22 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 40 | 20 | 47 | M64×2 | 165 | 115 | 6-26 | 28 | 65 | M80×3 | 200 | 145 | 6-29 | 40 | 165 | 165 | 350 | |

| 50 | 25 | 58 | M26×2 | 165 | 115 | 6-26 | 32 | 80 | M100×3 | 225 | 170 | 6-33 | 80 | 165 | 165 | 380 | |

| A41Y-320 | 10 | 8 | 18 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 |

| 15 | 8 | 27 | M33×2 | 105 | 68 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 20 | 10 | 30 | M36×2 | 110 | 75 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 25 | 12 | 35 | M42×2 | 115 | 80 | 4-18 | 22 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 32 | 12.14.16 | 41 | M48×2 | 135 | 95 | 4-22 | 25 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 40 | 20 | 58 | M64×3 | 165 | 115 | 6-26 | 32 | 65 | M80×3 | 200 | 145 | 6-29 | 40 | 165 | 115 | 350 | |

| 50 | 25 | 70 | M80×3 | 200 | 145 | 6-29 | 40 | 80 | M100×3 | 225 | 170 | 6-33 | 50 | 165 | 165 | 380 |

| A41C150, A41C150P, A41C150R | |||||||||||||||||

| Normal Diameter DN (in) |

Dimension (mm) | ||||||||||||||||

| do | D | D1 | D2 | b | t | z-¢d | DN' | D' | D1' | D2' | t' | b' | z-¢d' | L | L1 | H | |

| 1/2"×1/2" | D | 89 | 60.5 | 35 | 12 | 6 | 4-15 | 15 | 89 | 60.5 | 35 | 1.6 | 12 | 4-15 | 90 | 90 | 260 |

| 3/4"×1" | D | 98 | 70 | 43 | 14 | 6 | 4-15 | 25 | 108 | 79.5 | 51 | 1.6 | 15 | 4-15 | 96 | 92 | 280 |

| 1"×1" | D | 108 | 79.5 | 51 | 15 | 9 | 4-15 | 25 | 108 | 79.5 | 51 | 1.6 | 15 | 4-15 | 100 | 100 | 290 |

| 1"×2" | E | 108 | 79.5 | 51 | 15 | 9 | 4-15 | 50 | 152 | 120.5 | 92 | 1.6 | 18 | 4-19 | 114 | 105 | 290 |

| 1 1/2"×1 1/2" | G | 127 | 98.5 | 73 | 18 | 10 | 4-15 | 40 | 127 | 98.5 | 73 | 1.6 | 18 | 4-15 | 110 | 115 | 330 |

| 1 1/2"×2" | G | 127 | 98.5 | 73 | 18 | 10 | 4-15 | 50 | 152 | 120.5 | 98 | 1.6 | 18 | 4-19 | 110 | 115 | 330 |

| 2"×3" | J | 152 | 120.5 | 92 | 18 | 10 | 4-19 | 80 | 190 | 152.5 | 127 | 1.6 | 22 | 4-19 | 124 | 130 | 350 |

| A41C300, A41C300P, A41C300R | |||||||||||||||||

| Normal Diameter DN (in) |

Dimension (mm) | ||||||||||||||||

| do | D | D1 | D2 | b | t | z-¢d | DN' | D' | D1' | D2' | t' | b' | z-¢d' | L | L1 | H | |

| 1/2''×1/2'' | D | 95 | 66.5 | 35 | 15 | 6 | 4-15 | 15 | 89 | 60.5 | 35 | 1.6 | 12 | 4-15 | 90 | 90 | 260 |

| 3/4''×1'' | D | 117 | 85.5 | 43 | 16 | 10 | 4-19 | 25 | 108 | 79.5 | 51 | 1.6 | 15 | 4-15 | 96 | 92 | 280 |

| 1''×1'' | D | 124 | 90 | 51 | 18 | 6 | 4-19 | 25 | 108 | 79.5 | 51 | 1.6 | 15 | 4-15 | 100 | 100 | 290 |

| 1''×2'' | E | 124 | 90 | 51 | 18 | 6 | 4-19 | 50 | 152 | 120.5 | 92 | 1.6 | 18 | 4-19 | 114 | 105 | 290 |

| 1 1/2''×1 1/2'' | G | 156 | 114.5 | 73 | 20 | 9 | 4-22 | 40 | 127 | 98.5 | 73 | 1.6 | 18 | 4-15 | 110 | 115 | 330 |

| 1 1/2''×2'' | G | 156 | 114.5 | 73 | 20 | 9 | 4-22 | 50 | 152 | 120.5 | 92 | 1.6 | 18 | 4-19 | 110 | 115 | 330 |

| 2"×3" | J | 165 | 127 | 92 | 22 | 8 | 8-19 | 80 | 190 | 152.5 | 127 | 1.6 | 22 | 4-19 | 124 | 130 | 350 |

| A41C600, A41C600P, A41C600R | |||||||||||||||||

| Normal Diameter DN (in) |

Dimension (mm) | ||||||||||||||||

| do | D | D1 | D2 | b | t | z-¢d | DN' | D' | D1' | D2' | b' | t' | z-¢d' | L | L1 | H | |

| 3/4''×1'' | D | 117 | 82.5 | 43 | 16 | 6 | 4-15 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 105 | 110 | 280 |

| 1'' ×2'' | D | 124 | 90 | 51 | 20 | 9 | 4-19 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 115 | 105 | 290 |

| 1 1/2'' ×1 1/2'' | F | 156 | 114.5 | 73 | 22 | 10 | 4-22 | 40 | 127 | 98.5 | 73 | 18 | 1.6 | 4-15 | 147 | 165 | 330 |

| 1 1/2'' ×2'' | F | 156 | 114.5 | 73 | 22 | 10 | 4-22 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 147 | 165 | 350 |

All Categories

- Ball Valves

- Control Valves

- Check Valves

- Globe Valves

- Butterfly Valves

- Resilient Seated Gate Valves

- Pressure Reducing Valves

- Plug Valves

- Safety Valves

- Safety Relief Valves

- Bellows Sealed Valves

- Cast Steel Valves

- Forged Steel Valves

- Instrumentation Ball Valves

- Instrument Manifolds

- Needle & Gauge Valves

- Balance Valves