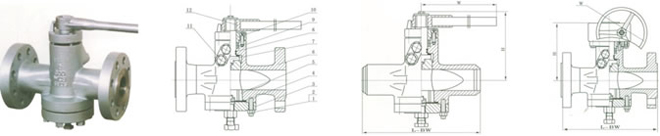

ANSI Severe Service Sleeved Plug Valves

Summary

Severe Service Sleeved Plug Valves according to ANSI is applicable to the cutting and connection of pipelines medium that aroused in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc. It is used under nominal pressure of CLASS150-1500LBS, and works at the temperature of -29~180°C.

a. The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance.

b. It has the structure of flip-chip balanceable pressure and light on/off operation.

c. An oil groove is set between valve body and seal surface, which may infuse the seal grease to increase the sea capability.

d. The materials of the parts and sizes of flanges can be configured reasonably according the actual operation condition the customer required, so as to meet the various needs of engineering.

Specifications

| Structural formation | BC |

| Diving manner | Hand-operated |

| Electric- operated | |

| Design standard | AP1599, AP16D |

| Face to face | ASME B16.10 |

| Flange end | ASME B 16.5 |

| Test &inspection | AP1598.AP16D |

Performances

| PN(LB) | Shell test (MPa) | Sealing test (MPa) | Suitable temperature | Suitable medium |

| 150 | 3.0 | 2.2 | =180°C | Water oil & |

| 300 | 7.5 | 5.5 | ||

| 600 | 15.0 | 11.0 | ||

| 900 | 22.5 | 16.5 |

ANSI Severe Service Sleeved Plug Valves

Materials

| NO | Part name | Material |

| 1 | Bolt | ASTM A 193-B7, A193-8, A193-B8M |

| 2 | Nut | ASTM A 194-2H, A194-8, A194-8M |

| 3 | Cover | ASTM A216-WCB ASTM A351-CF8,CF8M,CF3,CF3M |

| 4 | Gasket | Flexible graphite+stainless steel |

| 5 | Plug | ASTM A182-Gr.F6a ASTM A182-F22 ASTM A351-CF8,CR5M,CF3,CF3M |

| 6 | Body | ASTM A216-WCB ASTM A351-CF8,CF8M,CF3,CF3M |

| 7 | Stem | ASTM A182-Gr.F6a ASTM A182-F22 ASTM A182-F304,F316,F321,F304L,F316L |

| 8 | O ring | VITON |

| 9 | Packing | Flexible graphite+304 |

| 10 | Gland | ASTM A216-WCB ASTM A351-CF8,CF8M,CF3,CF3M |

| 11 | Oil nozzle | |

| 12 | Wrench | ASTM A47-32510, A216 WCB |

Dimensions and Weights

| Pressure | 150LB | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 245 | 267 | 292 | 330 | 356 | 381 | |

| L-BW | 152 | 178 | 203 | 216 | 229 | 267 | 305 | 330 | 356 | 381 | 394 | 457 | 533 | 610 | 686 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 500 | 600 | 600 | 820 | 820 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| Weight(kg) | 10 | 12 | 14 | 17 | 19 | 21 | 29 | 33 | 48 | 75 | 98 | 125 | 171 | 230 | 370 | |

| Pressure | 300LB | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | |

| L-BW | 152 | 178 | 203 | 216 | 229 | 267 | 305 | 330 | 356 | 381 | 457 | 521 | 550 | 635 | 762 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 600 | 600 | 820 | 1000 | 1000 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| Weight(kg) | 12 | 14 | 16 | 19 | 21 | 24 | 31 | 36 | 61 | 86 | 130 | 190 | 255 | 380 | 560 | |

| Pressure | 600LB | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RB.BW | 165 | 190 | 216 | 229 | 214 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 500 | 600 | 820 | 1000 | 1000 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| Weight(kg) | 14 | 16 | 18 | 20 | 24 | 29 | 35 | 47 | 91 | 129 | 210 | 320 | 660 | 920 | 1250 | |

| Pressure | 900LB | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RB.BW | 229 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 500 | 600 | 820 | 1000 | 1000 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| Weight(kg) | 17 | 29 | 21 | 24 | 30 | 37 | 44 | 65 | 110 | 160 | 255 | .380 | 810 | 1050 | 1460 | |

Note: 4" or above with gear

All Categories

- Ball Valves

- Control Valves

- Check Valves

- Globe Valves

- Butterfly Valves

- Resilient Seated Gate Valves

- Pressure Reducing Valves

- Plug Valves

- Safety Valves

- Safety Relief Valves

- Bellows Sealed Valves

- Cast Steel Valves

- Forged Steel Valves

- Instrumentation Ball Valves

- Instrument Manifolds

- Needle & Gauge Valves

- Balance Valves