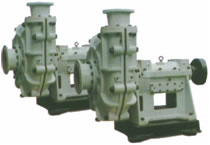

Slag Slurry Pump

I Summary For Slag Slurry Pump

Slag Slurry Pump

As a single-stage-single-suction horizontal cantilever-type centrifugal one, model ZM slag slurry pump is designed through absorbing advantages of similar products from home and aboard. It is convenient to install and easy to disassemble and repair. ZM slag slurry pump head part: Remy ZM slag slurry pump has double pump casings in structure. That is to say, it is made up of front pump casing, back pump casing, front guar plate, back guard plate, sheathing, shaft casing. The flow contact parts are made of JM3 materials, while the front and back pump casings are made of gray cast-iron or nodular cast iron, The outlets of the pump can be installed at the interval of 45℃,at eight angles, according to users requirements. At the front and back cover plates there are back blades to lower leakage, so as to extend the life and increase efficiency of the pump. The shaft seal part: The shaft seal has two forms: shaft seal of auxiliary blade wheel and filling seal. The shaft seal of auxiliary blade wheel is featured with not thinning ore slurry, long life of seal and good effect of seal, etc. The filling seal has simple structure and is convenient to repair. Drive part: Model ZM(slag) slurry pump can be directly driven. The bearing support, in combination with bearing body, has high strength in structure, big diameter of pump shaft, good flexibility, and short cantilever. Even if in bad working condition, no bending and vibration can arise. Because of using heavy single-line cone roller bearing, it can stand axial and radial loads of the pump. The shaft is lubricated with oil. At both ends of the bearing body there are bearing covers, inside of which there is seal ring. The ring can effectively protect ore slurry from penetration and the lubricating oil from leaking. This can make sure that the bearing can run safely. In accordance with users requirements, the drive part of the bearing can be in double-open type, and lubricated with thin oil. This can lower the temperature of the shaft.

II Property Parameters Table For Slag Slurry Pump

| model | head | capacity Q | Speed | Motor power | Permissible suctioned height | Efficiency h % |

|

| M3/h | L/S | ||||||

| 100ZM-25 | 23-30 | 150-500 | 14.6-55.5 | 1450 | 45 | 5.5 | 65-67 |

| 100ZM25A | 25-35 | 200-250 | 55.5-69.4 | 1450 | 55 | 5.5 | 65-67 |

| 100ZM-40 | 35-45 | 180-200 | 50-55.5 | 1450 | 55 | 5.5 | 43-48 |

| 100ZM-40A | 40-50 | 200-250 | 55.5-69.4 | 1450 | 75 | 5.5 | 70-75 |

| 100ZM-45 | 40-50 | 150-180 | 41.6-50 | 1450 | 55 | 5 | 50-60 |

| 100ZM-70 | 65-75 | 200-250 | 55.5-69.4 | 1450 | 110 | 5.5 | 55-60 |

| 100ZM-90 | 80-90 | 120-180 | 33.3-50 | 1450 | 110 | 5.5 | 50-55 |

| 150ZM-32 | 32-36 | 300-320 | 83.3-89 | 980 | 75 | 5 | 70-73 |

| 150ZM-32A | 32-36 | 420-450 | 116.6-125 | 980 | 90 | 5 | 70-73 |

| 150ZM-50 | 50-60 | 250-320 | 69.34-89 | 980 | 90 | 5 | 67-70 |

| 150ZM-50A | 50-60 | 400-450 | 111.1-125 | 980 | 132 | 5 | 67-70 |

| 150ZM-80 | 90-75 | 250-300 | 69.4-89 | 980 | 132 | 5 | 60-61 |

| 150ZM-100 | 95-105 | 400-450 | 116.6-125 | 980 | 250 | 5 | 60-64 |

| 200ZM-45 | 40-50 | 480-550 | 133.3-152.7 | 980 | 132 | 5.5 | 70-75 |

| 200ZM-45A | 40-50 | 680-750 | 1858.9-208.3 | 980 | 185 | 5.5 | 75-78 |

| 200ZM-75 | 70-80 | 450-550 | 125-153.7 | 980 | 250 | 5.5 | 70-75 |

| 200ZM-75A | 70-80 | 650-750 | 180.5-208.3 | 980 | 300 | 5.5 | 70-75 |

| 200ZM-95 | 90-100 | 480-580 | 133.3-161.1 | 980 | 320 | 5.5 | 55-58 |

| 200ZM-50 | 50-60 | 650-700 | 180.5-194 | 980 | 185 | 5.5 | 76-80 |

| 250ZM-50A | 50-60 | 950-1000 | 263.9-277.7 | 980 | 260 | 5.5 | 75-80 |

| 250ZM-85 | 80-90 | 630-700 | 175-194.4 | 980 | 320 | 5.5 | 70-72 |

| 250ZM-85A | 80-90 | 930-1000 | 258.3-277.7 | 980 | 450 | 5.5 | 70-73 |

| 250ZM-100 | 90-100 | 1000-1200 | 277.7-333.3 | 980 | 560 | 5.5 | 60-65 |

| 300ZM-40 | 40-50 | 1100-1200 | 305.5-333.3 | 730 | 270 | 4 | 75-80 |

| 300ZM-60 | 60-67 | 1500-1600 | 416.7-444.4 | 730 | 480 | 4.5 | 75-80 |

All Categories

- Diaphragm Pumps

- Split Case Pumps

- Centrifugal Pumps

- Multistage Pumps

- Submersible Wastewater, Sewage Pumps

- Vertical Submerged Pumps

- Sewage & Sludge Pumps

- Self Priming, Chemical Process Pumps

- Magnetic Drive Pumps

- Chemical Process Pumps

- In Line Pumps

- Oil Pumps

- Fire Protection Pumps

- Vacuum Pumps

- Screw Pumps

- Slurry Pumps