H42Y Flanged High Pressure Check Valve has the following three structural characteristics:

1. Upper and lower body adopt flange connection;

2. Manufacture and acceptance conditions are according to the provisions of JB 450.

3. The disc and seat sealing surface use stellite cobalt-based hard alloy welding, with wear-resistance, high temperature resistance, corrosive resistance, good anti-abrasion performance, long service life.

4. The high temperature pressure resistant components are made of high-quality heat-resistant alloy steel, with reliable safety, stable performance, long service life. The valve has been widely used in high-pressure pipelines of a variety of chemical industry, metallurgy, iron and steel industry.

Specifications

| Type |

Nominal Pressure

(MPa) |

Test Pressure (MPa) |

Working Pressure

(MPa) |

Working Temperature |

Working Fluid |

| seal |

Body |

| H42Y-160/320 |

16 |

17.6 |

24 |

16 |

≤200°C |

C: Nitrogen, Hydrogen, Ammonia |

| 32 |

35.2 |

48 |

32 |

| H42Y-220/320 |

22 |

24.2 |

33 |

22 |

≤200°C |

R: Urea Methylamine liquid |

| 32 |

35.2 |

48 |

32 |

Materials

| Name |

Materials |

| H42Y-160C, 320C |

H42W-220R, 320R |

| Body |

WCB |

SS 304 / 316 |

| Seat, Disc |

SS 2CR13 |

SS 304 / 316 |

| Spring |

Spring Steel 50CrVA |

SS 304 / 316 |

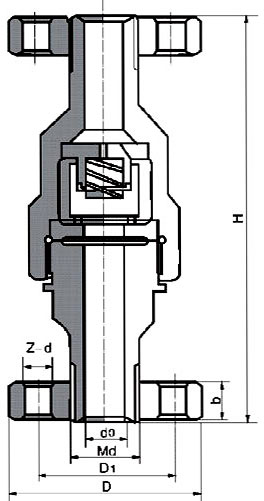

Dimensions and Weights

| Type |

Nominal Diameter

DN (mm) |

Dimensions (mm) |

| D |

D1 |

D2 |

Do |

b |

n-d |

L |

Weight / Kg |

| H42Y/W

160/220 |

10 |

135 |

60 |

95 |

12 |

20 |

3-Φ18 |

232 |

12 |

| 15 |

175 |

60 |

95 |

15 |

20 |

3-Φ18 |

288 |

12 |

| 25 |

190 |

68 |

105 |

23 |

20 |

3-Φ18 |

325 |

29 |

| 32 |

210 |

80 |

115 |

29 |

22 |

4-Φ18 |

350 |

43 |

| 40 |

265 |

115 |

165 |

39 |

28 |

6-Φ26 |

460 |

95 |

| 50 |

330 |

115 |

165 |

48 |

32 |

6-Φ26 |

505 |

115 |

| 65 |

360 |

145 |

200 |

61 |

40 |

6-Φ29 |

564 |

156 |

| 80 |

390 |

170 |

225 |

74 |

50 |

6-Φ33 |

700 |

246 |

| 100 |

430 |

195 |

260 |

93 |

60 |

6-Φ36 |

750 |

292 |

| 125 |

460 |

235 |

300 |

119 |

75 |

8-Φ39 |

789 |

351 |

| 150 |

500 |

255 |

330 |

136 |

78 |

8-Φ42 |

840 |

374 |

| 200 |

550 |

315 |

400 |

165 |

90 |

8-Φ48 |

900 |

480 |

| H42Y/W

220/320 |

10 |

135 |

60 |

95 |

10 |

20 |

3-Φ18 |

232 |

12.2 |

| 15 |

175 |

68 |

105 |

17 |

20 |

3-Φ18 |

288 |

12.2 |

| 25 |

190 |

80 |

115 |

23 |

22 |

4-Φ18 |

325 |

33.1 |

| 32 |

210 |

95 |

135 |

29 |

25 |

4-Φ22 |

350 |

46 |

| 40 |

265 |

115 |

165 |

42 |

32 |

6-Φ26 |

460 |

110 |

| 50 |

330 |

145 |

200 |

53 |

40 |

6-Φ29 |

505 |

130 |

| 65 |

360 |

170 |

225 |

68 |

50 |

6-Φ33 |

564 |

211 |

| 80 |

390 |

195 |

260 |

85 |

60 |

6-Φ36 |

700 |

341 |

| 100 |

430 |

235 |

300 |

103 |

75 |

8-Φ39 |

750 |

380 |

| 125 |

460 |

255 |

330 |

120 |

78 |

8-Φ42 |

789 |

435 |

| 150 |

500 |

315 |

400 |

136 |

90 |

8-Φ48 |

840 |

463 |

| 200 |

550 |

380 |

480 |

165 |

110 |

8-Φ55 |

900 |

502 |